Abstract

The performance of a textile mill is mainly determined by the loom-shed efficiency, which entirely depends upon the quality of sized beam production. During the processing of material in sizing, the yarns are stretched, which is one important factor to be considered in producing a quality-sized beam. The stretch caused by tension leads to an increase in length and reduction in yarn as well as fibre cross-section. This phenomenon affects the strength of the fibre. The required quality-sized yarn for good weaving performance is high elongation at break. If this falls below a certain limit then the warp breaks will increase on the loom. For better elongation at break the yarn stretch at sizing should be at the minimum possible level and, particularly, the stretch at wet zone should be as low as possible. This study mainly focused on control of stretch percent, and elongation of sized yarn and unsized yarn as factors in reducing the warp breaks on loom. The study was conducted for different counts as well as for cotton and cotton-polyester blend yarn.

Introduction

The following figure shows the main stretching zones in the sizing machine where the yarn is under tension. In the sizing machine the yarn is to be kept under tension during processing in order to avoid the slackness of yarn during processing, which results in entanglement of the yarns with each other. The tension on the yarn during sizing should be only up to a certain minimum level in order to avoid excess stress on the yarn, which may results in warp breaks on the loom due to the loss of yarn elongation at break. Table 1 shows the minimum level of yarn stretch for three different counts.

Various zones of stretch control on modern sizing machines are:

- Creel zone: Last warper beam to first squeezing roller

- Wet Zone: First squeezing roller to 2nd squeezing roller

- Drying Zone: First drying cylinder to last drying cylinder

- Splitting Zone: Last drying cylinder to drag roll

- Winding Zone : Drag roll to sizing beam

Stretch

When yarn is processed on a sizing machine the yarns are under tension. But this tension on the yarn during sizing is required, which results in a slight permanent stretch in the yarn. This permanent stretch causes decrease in elongation at break of sized yarn and this elongation in the yarn is called stretch. If the average extensibility of the sized yarn falls below a certain level, the less extensible portions in the yarn are likely to break during weaving.

Tensile Strength

The tensile strength of the yarn must be increased by the increase in fibre-to-fibre friction due to cementing of size film, as well as by the addition of strength by size film itself.

Flexibility

This property is particularly important in weaving. Sized warp yarn must be able to withstand repeated and extensive bending in the weaving operation without damaging the size film. Rupture of the film causes increased yarn friction in shedding and results in end break.

Elongation and Elasticity

Elongation is the amount of yarn stretch before it breaks. Elasticity is the property of yarn, which allows it to return almost to its original length after the stretching tension is released. Stretch is a factor that directly contributes to elasticity and elongation. After tensioning the yarn, stretch occurs in the fibre, in the size film and in the yarn itself. It is found that the amount of elongation and elasticity present in the sized yarn are directly related to the physical properties of the fibre and the properties of sizing materials used.

Material and Method

In this research study to test the effect of sizing stretch on end breakage rate at loom, yarns of three different count were selected, ie. 40s Ne, 45s Ne and 60s Ne. The selected yarns were stretched during the sizing process for five different stretching levels by adjusting creel tension as shown in Table 2. Then the five sized yarns of different stretching levels were tested for elongation at break and processed on loom to study the warp breakage rate.

Results and Discussion

In this research study five yarn samples of each count were taken, with five different yarn-stretch levels for each of the three different counts: viz. 40s Ne, 45s Ne and 60s Ne. Before the sized yarns were processed on loom their elongation at break was tested, by which it was possible to correlate this with warp breaks on loom. Table 3 shows the correlation of yarn elongation with the warp breaks at loom.

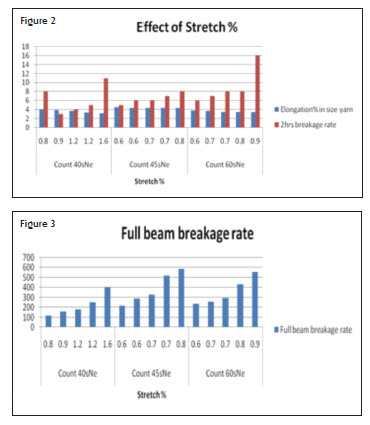

Table 3 and Figures 2-4 revels that, as the creel tension at sizing increases, the yarn elongation at break reduces due to higher stretching of yarn during sizing. By statistical analysis, ‘P’ value for elongation at break is 0.0002, which is less than 0.05, which confirms that there is a significant difference between the elongation percent for three different counts at five different yarn stretch levels.

It was also found that, if the yarn is given more tension during processing at sizing, its elongation at break reduces, which is reflected in an increase in warp breaks on loom. In a two-hour breakage study it was found that the increase in warp breaks was very pronounced for the highest stretch % for all counts, due to maximum loss in yarn elongation. For full beam breakage rate the study showed successive increase in warp breaks with increase in yarn stretch at sizing.

Figure 4 confirms that, as the yarn stretch at sizing increases, the size pickup of the yarn reduces due to increase in yarn tension during sizing. This is due to the increase in fibre packing density, caused by yarn compactness resulting from the higher yarn tension during sizing.

Conclusions

For 40s Ne yarn, if the yarn stretch at sizing is increased from 0.8% to 1.6% there is an increase in warp breakage rate on loom from 6.8 to 16.8 breaks/shift, due to reducing the yarn elongation by 20 to 25%. In the case of 45s Ne yarn, if the yarn stretch at sizing is increased from 0.6% to 0.8% there is an increase in warp breakage rate on loom from 5.1 to 17.3 breaks/shift, due to reducing the yarn elongation by 4.0 to 8.0%. The same trend is observed for the finer count.

The main reason for sizing the yarn is to improve its weavability by penetrating the size paste into to the yarn body as well as making a cover of size paste on the yarn body, but it is found that as the yarn stretch is increased during sizing the size pick-up by the yarn successively reduces, which directly results in increase in warp breaks on the loom.

By statistical analysis the ‘P’ value for warp breaks on loom due to reduction in size pick-up is 6.16E-09. It is less than 0.05, which confirms the dominant effect of size pick-up on warp breaks on loom.

References

- M.C.Paliwal and P.D. kimoti – Process Control in Weaving Published by Dr. N.E. Dweltz and shri R.C.Vohra for second Edition (Nov. 1974) Page no. 109 to 118.

- M.C.Paliwal, P.D. Kimoti and Subramanian T.A. Process Control in Sizing Published by R.C. Vora for ATIRA. First Edition (April 1987) Page no. 16 to 24.

- Agrawal S.K. and Bai Subramanin Contribution of same variables to the Weavability of yarn, Part second Contribution of Stretch ATIRA Publication (Nov. 1986).

- Impact of stretch % and elongation% on loom performance, www.fiber2fasion.com

- Stretch% and elongation% in sizing: www. google.com.