In recent years the demographical ageing impact of the European population has been witnessed, and Eurostat’s population projections foresee that this ageing process will continue into future decades.

It is caused by different aspects in society, but particularly due to the increased number of people living longer (life expectancy) and a relatively low birth rate, which has been sustained for a number of decades [1]. There is no doubt that the European population is ageing rapidly (Figure 1) and this is becoming a driving force in our society [2, 3]:

- Over the last century the average life expectancy in Europe has increased for males from 45.7 to 75 years, and for females from 49.6 to 79.9 years.

- Those aged over 65 will rise from 16.6% to 29.6% by 2060 (increase of 65.1 million people).

- Furthermore, the proportion of very old people (aged 80 and above) in the EU-27 will grow from 5% in 2010 to reach 6% by 2025 and 12% by 2060.

- Eurostat's old-age dependency ratio for the EU-27 is projected to increase from 25.9% (2010) to 52.5% (2060).

Senior citizens have specific needs for clothing, assistive fabrics and other textile products fundamental to personal, hygiene and medical products that are an essential part of their daily life. Innovation in these areas has the potential to benefit millions of elderly lives, from both groups across Europe, by significantly facilitating and enhancing quality of lives.

The Textiles for Ageing Society (TAGS) Project

The primary target of the TAGS project is improving the quality of elderly peoples’ lives; key factors include wellbeing, towards health, social and informal care to match the individual’s needs; this requires ‘joined-up’ thinking by researchers, policy-makers and care agencies on the ground.

As part of a four year project, funded by the European Commission with a budget of €1.12 million, a network of materials laboratories and innovation players in industrial sectors for product innovation, coordination and support actions will be formed.

The technical scope of the project which started on January 1, 2012, and will run to December 31, 2014, will:

- Form new alliances to mobilise and bring together all the right actors and to broker collaboration between materials research and industrial entrepreneurs.

- Stimulate the creation of dynamic alliances between material researchers and creative industries.

- The determination of the added value, aiming at constituting teams of innovators, able to close the loop from the laboratories to a product, or a novel industrial process.

- Actors competent in other aspects boost competitiveness and accelerate success (metrology, standardisation, socio-economic, health or environmental impact, regulation).

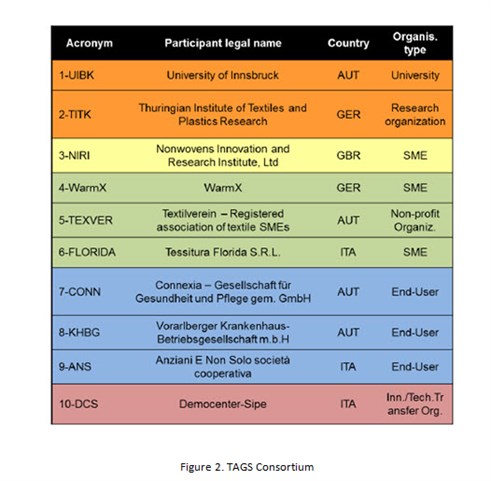

The aim of the “TAGS” consortium is to bring together the elderly via social and medical care institutions, research institutions, technology transfer institutions and manufacturers to identify: specific requirements of the elderly and care institutions; latest developments in materials science and technology; and strategies to incorporate developments in the manufacturing chain. Hence, the partners are covering all these areas of expertise (see Figure 2).

The main objectives of “TAGS” is to: identify new materials, techniques, and technologies based on demands and requirements formulated by end-users and industry towards improving textile products; to assess the scope, boundary conditions for innovation and identify barriers preventing progress; to initiate active discussion and dissemination of information; to generate new joint and collaborative concepts, joint research activities; and to formulate recommendations for policy makers.

The main objectives of “TAGS” is to: identify new materials, techniques, and technologies based on demands and requirements formulated by end-users and industry towards improving textile products; to assess the scope, boundary conditions for innovation and identify barriers preventing progress; to initiate active discussion and dissemination of information; to generate new joint and collaborative concepts, joint research activities; and to formulate recommendations for policy makers.The main fields of TAGS interest were set up in:

- Bedding textiles

- Clothing

- Textile products for hygiene and personal care

- Therapeutic and recreational/leisure textiles.

The project started with the collection of available information; like the identification of state of the art technology, problem areas, demands, and definitions of requirements. This will be followed by creating a common understanding between research institutions, industrial partners and end-users to develop new concepts/ideas towards new projects and new innovative products based on elderly demands (Figure 3).

Work performed and selected outcomes

The survey research, the questionnaires and personal interviews of elderly and care-givers about bedding textiles and clothing were prepared in order to gain their assessment of textile products, particularly bedding textiles and clothing.

Importantly, it links the knowledge and experience of care homes to research institutions and manufacturers, to better understand the needs, requirements, and barriers which will help to develop new, beneficial, and effective products for elderly people towards improving their quality of life.

Primarily, the focus is on appearance, functionality, comfort, convenience, care, safety, durability of available products or products used the most. Non-technological (cultural, psychological, etc.) barriers of both end-users and care-givers preventing development in textiles for ageing people have also been identified.

Additionally, demands and requirements on materials, products, processes, and garment design are to be formulated going forward. Consideration of sustainability factors such eco-friendly production, life cycle analysis, environmental impact, carbon footprint, water footprint, or eco branding is also of interest.

So far, first trials have been performed in Austria (Vorarlberg region), Italy (Modena region), and the United Kingdom (Yorkshire). These findings are based on the number of respondents from Austria (575) and Italy (565). The data from Austria and Italy showed the lack of knowledge of the caregivers in the field of new materials that are available on the market owing to the preference to use products made from natural materials. Also another interesting conclusion reflects the difference in the climate of both countries.

The Majority of respondents (in Austria about 95%, and in Italy about 90%) would prefer to have their bedding made from natural materials such as cotton, wool, viscose, etc. despite the fact that some synthetics or “new” materials may provide advantageous performance.

It is thought that it is because older persons are more familiar with those materials, and the tradition of usage of natural materials. However, about 90% of Austrians answered that their beddings are made from cotton, and some (each about 5%) made from viscose, bamboo, silk, or linen.

Every Italian respondent has beddings made from cotton (100%), but also some beddings in use are made from synthetics such as polypropylene (about 20%).

Caregivers have also stated that peopler prefer beddings with enhanced functionalities such as increased breathability, heat and moisture transition, better barrier functions and/or liquid absorption features such as water/liquid resistance or absorbance, as well as additional functions like easy-care (no ironing), and devices to help position patients (Figure 4).

Caregivers themselves would also prefer some functionalities for the bedding, and the most requested are dedicated to design like touch of the material (softness, smooth, coarse, etc.), style/design of beddings (appearance), and colours, and functionalities affecting the sleep such as quality of sleep, feeling warm or cool in bed, and to be covered while in bed (Figure 5).

Information about sleeping and living condition in care homes have also been collected. The key factors for elderly people to sleep comfortable are:

- adjustable bed,

- mattress, and

- anti-wound mattress.

- adjustable bed,

- mattress,

- anti-wound mattress, and

- sheets which protect from damp feel in bed.

Another issue revealed by the questionnaires was the weight of the blanket; often it is rather heavy and does not cover the patients well.

According to the caregivers, there are also a number of weaknesses with regards to the bedding materials, such as:

- covers for pillows and quilts do not fit – inlet too large or too small,

- sterile look,

- older material soft, new material harder – denser,

- issues with regards to wear and tear,

- lack of breathability,

- closures not good, and

- the fit of bedclothes to quilt is not appropriate.

Following a number of brainstorming sessions with experts, the consortium has looked at developing a number of techniques and portfolios to transfer the knowledge of the experts into action. For selected topics, at this stage, bedding textiles and clothing, the involvement of external experts such as medical doctors, psychologists, social scientists, product designers, specialists for health and care, experts for materials and production technology as well as professional and family caregivers have played a considerable part.

These experts were invited from other European countries, in addition to the countries participating in the project, to bring their knowledge and perspective on the various topics.

The discussions during and after the lectures, and brainstorming sessions, are looking to generate ideas that will improve the quality of life for ageing individuals and will help caregivers deliver care more effectively by means of, for example, improving textile performance, smart textiles, useful advantages of raw materials, polices, propose guides, etc. Importantly, the needs and requests of both care recipients (elderly) and caregivers will be considered and followed.

Summary

So far, the project has succeeded in gaining the perspective of the actual end-users of textiles for the elderly, not only the managers in the care homes and hospitals, but also relatives, nurses, care-givers and doctors who deal with clothing, bedding and incontinence products for the elderly on a daily basis.

However, as the four year project is only one year in there is plenty of work to be done. What has been noted is that developing functional bedding with the right qualities can be challenging.

For instance, bedding as a system has to manage sweat (humidity) and liquids to protect mattresses from liquid, and for hygiene impermeable layers (mattress-stopper). But this increase of moisture/liquid content can result in skin damage (e.g. decubitus) due to the combination of moisture, friction and the fact that mattresses are made from closed foam materials.

Open foam would be preferable, according to experts. However, then the liquid barrier – mattress-stopper would also be moisture permeable. The project, so far, has suggested that bedding systems need to be treated as one; each layer has a specific role with its own specific micro climate. But more research needs to be conducted into producing textiles for the ageing European community.

References

1. i2010: Independent Living for the Ageing Society (2007) http://ec.europa.eu/information_society/activities/policy_link/brochures/documents/independent_living.pdf

2. European Commision “Eurostat” (data from October 2011) http://epp.eurostat.ec.europa.eu/statistics_explained/index.php/Population_structure_and_ageing#

3. European Commision “Eurostat” (data from 20.12.2011) http://epp.eurostat.ec.europa.eu/tgm/refreshTableAction.do?tab=table&plugin=1&pcode=tsdde511&language=en