In our recent InfoTrends study called ‘Transforming Textile Printing’ our team took an in-depth look at opportunities for digital printing in the textile market. The potential for digital printing to influence the printed-textile market has long been promised, yet less than 1.5% of printed textiles are digitally printed today.

The textile market is a vast business, easily surpassing $1 trillion in annual revenue on a worldwide basis. Encapsulated in this number is the ‘printed’ textile volume, which is more than $165 billion, and yet nested within that is a digital-textile printing segment which InfoTrends believes is valued at more than $10 billion worldwide.

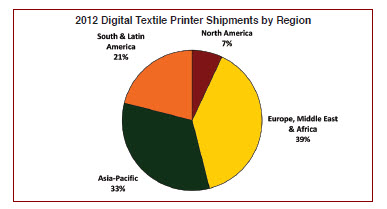

The global nature of this market is extremely important, because the textile business is critical to some of the world’s largest and fastest growing economies. In fact, adoption of digital-textile printing systems is a global phenomenon, as none of the major printed-textile regions can afford to be left behind in terms of their ability to meet the changing demands of the market. The market is led by the Europeans, where many of the top fashion centres and leading brands reside, but there are growing markets for digital-textile printing systems worldwide. What we learned as a result of this study is that changing dynamics in brand management, as well as retail go-to-market, present an enormous potential for high-speed digital textile printing systems over and beyond the forecast period. These changes include: increasing number of fashion seasons and the resulting demand for faster cycle times; a trend to shorter run lengths; and the desire to mitigate risks for unused/unsold textile-based products.

At the same time, on the technology side, there has been a generational leap forward with the recent introduction of high-speed systems that are more competitive with screen and gravure textile printing both in terms of production speeds and costs. The use of high-quality, high-speed inkjet print-head technology in these high-end systems enables production of hundreds, and even thousands of square metres per hour that are robust enough to run 24 hours a day, 7 days a week.

The combination of all of these factors will lead to a rapid adoption of digital-textile printing systems. InfoTrends is forecasting an overall compound annual growth rate of more than 28%, and more than 42% among the production-oriented high-end digital-textile printing systems.

This confluence of factors is driving change in the textile market and is expected to drive investment in digital-textile printing systems and usage through the present forecast period. The increasing ability of textile producers to respond to demand for faster cycle times is provided by digital printing.

While many traditional textile-printing companies are adopting digital printing, the developments cited in this InfoTrends research also have enabled the emergence of web-based companies, which specialise in short-run digital-textile production and provide these services to global businesses and consumers by employing digital-textile production workflows that are more efficient and faster than the traditional textile supply chain could offer.