Assessing water related impacts in an objective manner will benefit the textile industry in many ways, providing a consistent, scientific basis for reporting water-footprint results.

In 2009 the International Organization for Standardization (ISO) therefore formed Working Group 8 (WG8), which is made up of about 80 experts delegated from about 40 countries and major organisations. It has since met twice a year, with the goal of delivering an International Standard, numbered 14046, that clarifies principles, requirements and guidelines to assess the water footprint of products, processes and organisations within the context of environmental management.

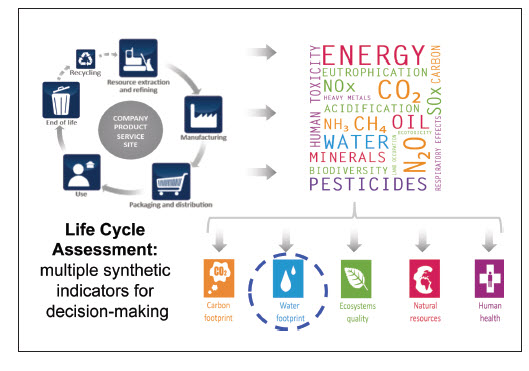

The major principle that WG8 has been working to is based on the lifecycle-assessment approach – as defined in ISO 14044. It therefore considers, when relevant, all issues related to water throughout the lifecycle of the product, process or organisation assessed.

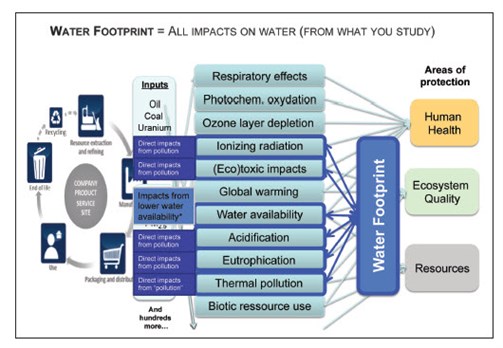

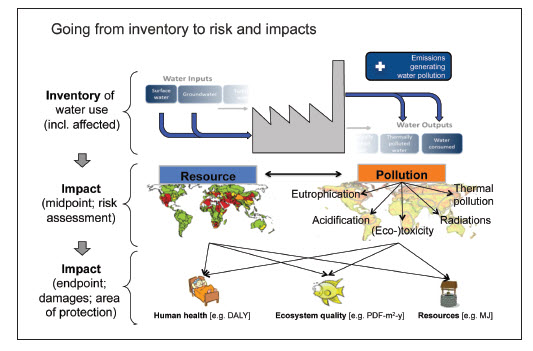

Basically the Standard looks at: (i) issues related both to water consumption and to water pollution; and (ii) not only the quantity of water consumed and/or polluted but also at the impacts caused by water consumption and pollution. These issues can be very different in different regions of the world.

Four Stage Approach

This latest International Standard proposes that the water-footprint assessment is carried out in a four-stage approach. It starts with the clear definition of the goal and scope of the study; followed by an inventory analysis (ie. amount of water used, consumed and polluted throughout the lifecycle of the product, process or organisation assessed); then the impacts associated with water are assessed (the so-called ‘water footprint impact assessment’); and finally the results are interpreted in an objective and scientific manner and, depending on the goal and scope, recommendations are made.

In practice this means that one starts by collecting data at the factory level and/or from the suppliers throughout the supply chain. This data is typically the amount of water consumed and the amount of water polluted, as well as how much and what types of pollutants are emitted.

For example, if you evaluate the textile sector, the amount of water used to irrigate the cotton field, the amount of fertilisers and pesticides used in the cotton field, the amount of water used at the factory, and the amount of pollutants released into the river by the factory, are all taken into account. Then the impacts caused by the water consumed and polluted are calculated using maps and models showing, for instance, how badly the water supply at the factory location is stressed or how sensitive to eutrophication the rivers in that region are.

At the end of the process, the goal is to have a complete view of the degrees of impact associated with water at the different sites and throughout the supply chain.

It is expected that – as this International Standard provides transparency, consistency, reproducibility, and credibility for assessing and reporting the water footprint of products, processes and companies – it will benefit organisations, governments and other interested parties worldwide, which are interested in such information.

Demand for Information

There is clearly an increase in demand for such information: for example, the French and EU projects on the labelling of products, and also demand from stakeholders challenging textile companies about potential issues related to water throughout their supply chain.

Overall, assessing water-related impacts in an objective way will benefit the textile sector in many ways. For instance, it can help in:

• assessing the magnitude of potential environmental impact(s) related to water from different companies or products

• identifying opportunities to reduce water related potential impacts associated with textile products at various stages in their life cycle as well as processes and organisations

• strategic risk management related to water

• facilitating water efficiency and optimisation of water management at product, process, and organisational levels

• informing decision-makers in industry, government or non-governmental organisations of their potential impacts related to water (eg. for the purpose of strategic planning, priority setting, product or process design or redesign, decisions about investment of resources)

• providing consistent and reliable information, based on scientific evidence, for the reporting of water footprint results

Many stakeholders in the textile sector already use some sort of water-footprint assessment – as, for example, Levis, Nike and the Higg Index by the Sustainable Apparel Coalition (SAC). These projects have already proved to be beneficial for the firms and associations involved.

However, the water-footprint community knows that from these studies, and from a broader perspective, the textile sector has some key challenges to address in areas such as irrigation for agricultural-based raw fibres (eg. cotton), wastewater from dyeing plants, and consumer use of products, as well as their engagement with the issue.

Lack of Consistency

One of the drawbacks of the existing projects is a lack of consistency between them, and comparisons are not directly possible, as some aspects of the water-footprint studies are questionable, or are not scientifically sound enough, and system boundaries can be typically different. Thus, standardisation will provide the entire sector with a reference document, allowing companies to be aligned with an internationally recognised model for best practice. This will bring credibility to all the existing projects, when aligned, and ensure the comparability/consistency of future projects.

In addition, some firms have not spent much energy looking at the issue of their water footprint – due to a lack of coherence between initiatives and some confusion that exists now. ISO 14046 will provide both confidence and a tool for these companies to go forward and better manage their water use.

Overall, this standard should not be seen as a constraint, but as an opportunity to ensure the credibility of existing initiatives, projects and efforts, and to catalyse new stronger projects in water stewardship.

Water assessment, as described in ISO 14046, is part of a broader field of water management and stewardship. Many textile companies have already worked on this subject, at least at compliance level. And ensuring a good water management and stewardship is mandatory to ensure that business goals are respected for those companies. This latest standard requires them to engage with stakeholders at a different level:

• Investors relations (through extra-financial reporting, Corporate Social Responsibility (CSR) reporting, Carbon Disclosure Project (CDP) or (Dow Jones Sustainability Index (DJSI) reporting, etc)

• Consumers (through labelling or communication/marketing)

• Communities (to ensure licence to operate but also to mitigate potential risks and manage brand image)

• Authorities (to ensure licence to operate, solve social issues and mitigate potential risks)

• Employees (to ensure the best efficiency and working conditions, as well adherence to corporate culture)

Water stewardship should not be considered only in relation to the operational scope of one company, but at a broader level along its value chain. All this complexity needs to be managed and, as it is often said, what gets measured gets managed. ISO 14046 serves this measurement goal and will ensure the provision of relevant insights and facts for the achievement of water-stewardship excellence.